APPLICATORS

Diaphragm pumps (MP series)

The MP series are diaphragm pumps capable of high capacity and high pressure. It is suitable for use on big machinery, like self-propelled harvesters.

High pressure

The MP series operate with a pressure of up to 2,8 bar in order to handle the lifting height needed on larger machinery.

MP12

MP12 is a diaphragm pump delivering up to 12 liters per minute. MP12 is suitable for use on round balers and loading wagons.

TECHNICAL DETAILS

MP12

| Voltage | 12 V |

| Max Current | 8 A |

| Min Flow | 1,7 l/min |

| Max Flow | 11 l/min |

| Max flow with stainless spray boom and 10m hose | 9,5 l/min |

| Max Pressure | 2,8 bar |

MP17

MP17 is a diaphragm pump delivering up to 17 liters per minute. MP17 is suitable for use on equipment demanding high capacity and flow like self-propelled harvesters.

TECHNICAL DETAILS

MP17

| Voltage | 12 V |

| Current | 13 A |

| Min Flow | 3,7 l/min |

| Max Flow | 14 l/min |

| Max flow with stainless spray boom and 10m hose | 11 l/min |

| Max Pressure | 2,8 bar |

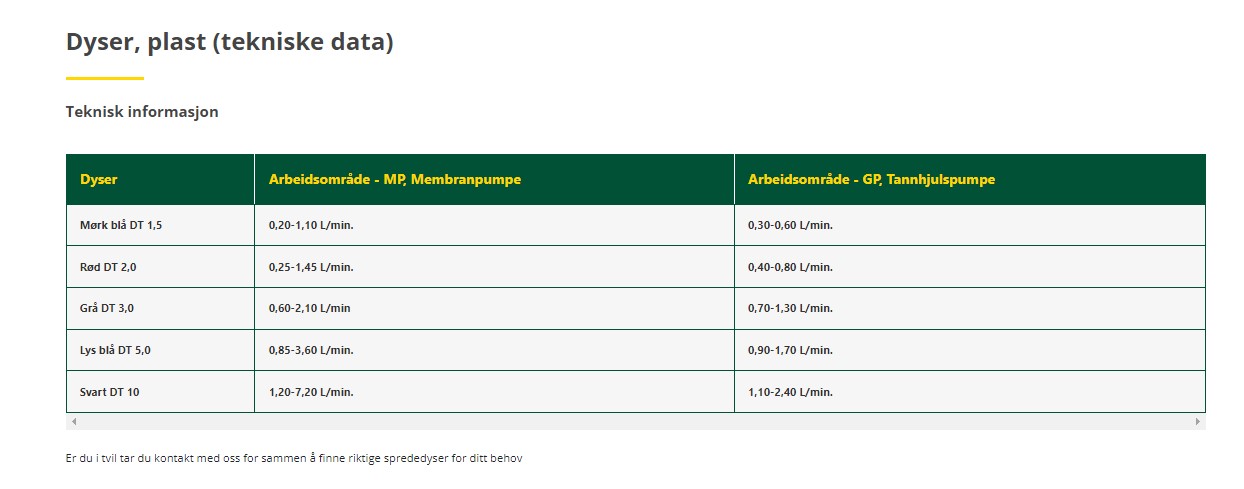

Nozzles

Choosing the right nozzles is essential for achieving desired spray and capacity. Have a look in our nozzle chart to find the correct nozzles.

-

nozzle chart

Spray nozzles

Standard spray solution with two nozzles mounted on flexible hoses, for easy and custumizable setup.

Spray boom

The spray boom is available in lengths of 60 or 120 cm, with respectively 2 or 5 nozzles. We also deliver a sprinkler boom with holes instead of nozzles in lengths of 50 or 100 cm.

Magnetic valve

The magnetic limits spilling of acid if the outlet is placed below the tank. A certain pressure is required to open the valve, and is configurable with one or two magnets to adjust the opening resistance.

Pickup switch

Mechanical switch that control the pump when the pickup is lowered or raised.

Quick release

Quick releases on the hose makes connecting and disconnecting very easy.

General

- Check pump, pumping chamber and filter regularly.

- Check electrical connections for corrosion and wear

- Check hoses and gaskets for leaks and wear

- Flush pump with water before storage

- Store in a dry and frost-free environment

Gaskets and hoses

Check hoses and gaskets for breakage and leaks on a regular basis. Replace worn components if needed.

Foreign objects

Check filter and nozzles for foreign objects that may limit functionality of the pump.